Diametro Optimo Chimenea

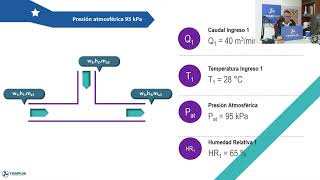

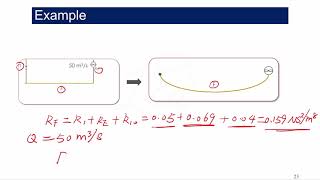

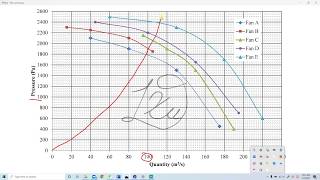

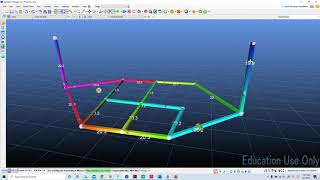

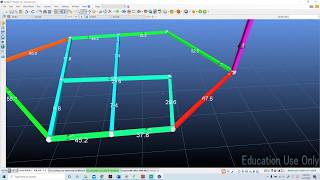

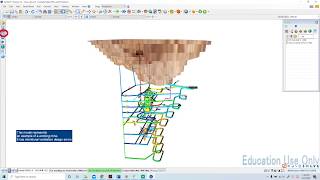

Alguna vez has tenido la tarea de determinar el diámetro optimo de una Chimenea de ventilación en una mina "x". Problemas con el cálculo del diámetro óptimo de una chimenea de ventilación. Bien a menudo me preguntan sobre el desarrollo de este mismo, y la verdad lo he visto calcular de diferentes maneras. 1️⃣ 𝗟𝗮 𝗽𝗿𝗶𝗺𝗲𝗿𝗮 𝗙𝗼𝗿𝗺𝗮 𝗲𝘀 𝗴𝗲𝗻𝗲𝗿𝗮𝗻𝗱𝗼 𝘂𝗻 𝗖𝗼𝘀𝘁𝗼 𝗱𝗲 𝗩𝗲𝗻𝘁𝗶𝗹𝗮𝗰𝗶𝗼́𝗻 𝗲𝗻 𝘂𝗻 𝗮ñ𝗼, 𝗰𝗼𝗺𝗼 𝗿𝗲𝗮𝗹𝗶𝘇𝗼 𝗲𝘀𝘁𝗼?, 𝗱𝗲 𝗹𝗮 𝘀𝗶𝗴𝘂𝗶𝗲𝗻𝘁𝗲 𝗳𝗼𝗿𝗺𝗮: - 🏬 𝗖𝗼𝘀𝘁𝗼 𝗱𝗲 𝗜𝗻𝘃𝗲𝗿𝘀𝗶𝗼́𝗻: Es aquel aquel costo de capital que se invierte para construir la Chimenea RB y/o RC, es cual tenga un precio unitario por metro lineal y un costo fijo por traslado e instalación de la maquina por posicionamiento. 👀 𝘌𝘴𝘵𝘦 𝘤𝘰𝘴𝘵𝘰 𝘥𝘦 𝘪𝘯𝘷𝘦𝘳𝘴𝘪𝘰́𝘯 𝘴𝘦𝘳𝘢́ 𝘢𝘯𝘶𝘢𝘭𝘪𝘻𝘢𝘥𝘢 𝘤𝘰𝘯 𝘶𝘯𝘢 𝘵𝘢𝘴𝘢 𝘥𝘦 𝘳𝘦𝘧𝘦𝘳𝘦𝘯𝘤𝘪𝘢 𝘥𝘦𝘭 𝘮𝘦𝘳𝘤𝘢𝘥𝘰 𝘦𝘯 𝘦𝘭 𝘤𝘶𝘢𝘭 𝘦𝘴𝘵𝘦́𝘴 𝘵𝘶 𝘭𝘢𝘣𝘰𝘳𝘢𝘯𝘥𝘰 (𝘌𝘯 𝘮𝘪 𝘤𝘢𝘴𝘰 𝘭𝘰 𝘨𝘦𝘯𝘦𝘳𝘢 𝘭𝘢 𝘚𝘉𝘚). - 🌪 𝗖𝗼𝘀𝘁𝗼 𝗱𝗲 𝗢𝗽𝗲𝗿𝗮𝗰𝗶𝗼́𝗻: Es aquel costo operativo que gastara para mover una cantidad de flujo de aire por la chimenea RB y/o RC, el cual estará afecto el diámetro, perímetro, factor de fricción, densidad, Factor de Choque X0,Longitud de Chimenea y el tarifario de energía ($/Kwhr). 2️⃣ 𝗟𝗮 𝘀𝗲𝗴𝘂𝗻𝗱𝗮 𝗳𝗼𝗿𝗺𝗮 𝗲𝘀 𝗰𝗮𝗹𝗰𝘂𝗹𝗮𝗿 𝘂𝗻 𝗩𝗔𝗡 𝗱𝗲𝗹 𝗰𝗼𝘀𝘁𝗼 𝗱𝗲 𝗶𝗻𝘃𝗲𝗿𝘀𝗶𝗼́𝗻 𝗲𝗻 𝗲𝗹 𝗮ñ𝗼 "𝟬" 𝘆 𝘂𝗻 𝗰𝗼𝘀𝘁𝗼 𝗱𝗲 𝗼𝗽𝗲𝗿𝗮𝗰𝗶𝗼́𝗻 𝗽𝗼𝗿 𝗮ñ𝗼, 𝗮𝘀𝗶𝗴𝗻𝗮𝗻𝗱𝗼𝗹𝗲 𝗹𝗮 𝗰𝗮𝗻𝘁𝗶𝗱𝗮𝗱 𝗱𝗲 𝗮ñ𝗼𝘀 𝗾𝘂𝗲 𝘃𝗮 𝗱𝘂𝗿𝗮𝗿 𝗲𝗹 𝗽𝗿𝗼𝘆𝗲𝗰𝘁𝗼. 3️⃣ 𝗠𝗲𝗱𝗶𝗮𝗻𝘁𝗲 𝗲𝗹 𝘀𝗼𝗳𝘁𝘄𝗮𝗿𝗲 𝗩𝗲𝗻𝘁𝘀𝗶𝗺, 𝗘𝗹 𝗰𝘂𝗮𝗹 𝗮 𝗽𝗮𝗿𝘁𝗶𝗿 𝗱𝗲𝗹 𝗺𝗼𝗱𝗲𝗹𝗼 𝗰𝗮𝗹𝗶𝗯𝗿𝗮𝗱𝗼 𝗴𝗲𝗻𝗲𝗿𝗮 𝘂𝗻𝗮 𝘀𝗶𝗺𝘂𝗹𝗮𝗰𝗶𝗼́𝗻 𝗳𝗶𝗻𝗮𝗻𝗰𝗶𝗲𝗿𝗮 𝗽𝗮𝗿𝗮 𝗲𝗹 𝗰á𝗹𝗰𝘂𝗹𝗼 𝗱𝗲𝗹 𝗱𝗶𝗮́𝗺𝗲𝘁𝗿𝗼 ó𝗽𝘁𝗶𝗺𝗼. 🥇 Para mi lo más ideal es la 2da forma y es cuando anualizas los costos de inversión (hashtag#Capex), con los costos de operación (hashtag#Opex) y lo llevas a una unidad base 💸 US$/m. Con la información de Geología y Mina, estimaras los años que te va durar este proyecto (3-5-10 años), y en base esta proyección realizaras una simulación anualizada para traer el VAN por cada diámetro de chimenea. Se debe tener en cuenta que tanto la inversión y el gasto de operación ingresan de forma negativa en la caja de la mina "X" por lo tanto el VAN que se seleccione será el que este más próximo a Cero, que se entiende que es el mejor VAN entre los demás.